In my journey of maintaining outdoor machinery, I’ve come to realize the vital importance of ensuring that the energy source is functioning optimally. A reliable power supply is fundamental for seamless operation and longevity of any equipment. It is essential to have a clear understanding of how to assess the performance of this critical component, as well as to identify any potential issues that may arise over time.

With experience, I learned that a few simple steps can provide valuable insights into the performance of the energy management apparatus. By adopting a systematic approach, one can easily uncover whether the apparatus is operating as intended or if there are underlying complications that need attention. This process not only enhances efficiency but also extends the lifespan of the machinery.

Throughout this exploration, I will share my insights and techniques for evaluating the functionality of the energy supply mechanism. By the end, I hope to empower you with the knowledge to ensure your equipment remains in peak condition, ready to tackle any outdoor task with confidence and reliability.

Common Signs of Charging Issues

As I delve into the intricacies of small engine maintenance, I’ve come to realize that recognizing when something is amiss can save both time and effort. There are several indicators that suggest the power generation component is not functioning as it should. By paying close attention to these signs, I can ensure that my equipment operates smoothly and efficiently.

1. Dimming Lights: One of the first things I’ve noticed is when the lights on my equipment appear to be dimmer than usual. This often indicates that the electrical flow is insufficient, suggesting a potential problem with the generator or related components. When I notice this, I make a mental note to investigate further.

2. Difficulty Starting: Another clear sign that I’ve encountered is trouble starting the engine. If I find myself repeatedly pulling the starter cord without success, it may indicate that the power supply is compromised. Often, this issue arises because the battery isn’t being adequately charged during operation.

3. Unexpected Shutdowns: I’ve had experiences where my machinery suddenly shuts off during use. This abrupt stop can be alarming and is frequently a sign that the power supply is unstable. If this happens, I take it as a serious indication that I need to check the electrical components.

4. Corroded Connections: Upon inspection, I sometimes discover corroded or loose connections. This is a common culprit for electrical issues. The corrosion can interrupt the flow of electricity, causing various performance problems. I make it a point to clean and secure these connections whenever I observe signs of rust or wear.

5. Battery Issues: Lastly, a battery that consistently fails to hold a charge is a clear indication that something is wrong. If I find that I need to replace the battery frequently, I suspect that the power generation unit isn’t functioning properly. This is another area that requires close attention during my maintenance routine.

By being vigilant and aware of these common signs, I can take proactive measures to address any underlying issues before they escalate. Understanding these indicators not only enhances my efficiency but also prolongs the lifespan of my equipment.

Essential Tools for Evaluation

In my experience, having the right tools on hand is crucial when it comes to inspecting the electrical components of outdoor equipment. Each tool serves a specific purpose and can significantly streamline the evaluation process. Below, I’ll outline the essential instruments that I find indispensable for this task.

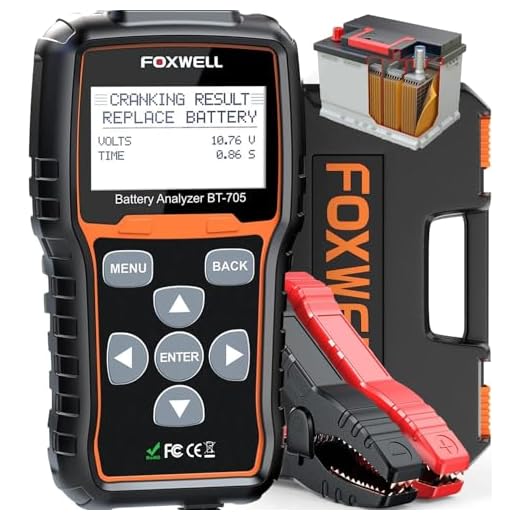

- Multimeter: This versatile device is vital for measuring voltage, current, and resistance. It allows me to check the output of various components and ensures they are functioning within the expected range.

- Screwdrivers: A set of screwdrivers, both flathead and Phillips, is necessary for accessing the internal parts. Different models may require different sizes, so having a complete set is beneficial.

- Wrenches: Adjustable wrenches or socket sets are important for loosening and tightening bolts as I work on different components. Ensuring connections are secure is key to proper functionality.

- Wire Strippers: These are essential for dealing with electrical wiring. If I need to replace any wires or make new connections, having a reliable wire stripper ensures clean and effective work.

- Safety Gear: Protective eyewear and gloves should always be a priority. Safety is paramount when working with electrical systems to prevent any accidents.

Having these tools readily available not only makes the evaluation process more efficient but also enhances safety and accuracy. Each instrument plays a role in diagnosing potential problems, making my work smoother and more effective.

In summary, equipping myself with the appropriate tools is a foundational step in ensuring a thorough and successful evaluation of outdoor equipment’s electrical components. With the right instruments, I feel more confident in identifying issues and implementing solutions.

Step-by-Step Evaluation of the Power Supply Mechanism

In this section, I will guide you through a detailed examination of the energy generation and distribution apparatus found in outdoor machinery. Understanding the intricacies of this mechanism is crucial for ensuring that your equipment operates efficiently and reliably. By following these steps, I aim to provide clarity on the process and help you identify potential issues effectively.

First, it is essential to ensure that the equipment is safely powered down before beginning any evaluation. This precaution helps prevent accidents and ensures that I can work without interruptions. I will then check the primary connections for any signs of wear or corrosion. Corrosion can impede the flow of electricity, leading to various performance problems.

Next, I will examine the components involved in energy generation. It is important to inspect the generator for any visible damage or debris that may hinder its functionality. A clean and intact generator is vital for optimal performance. I will also verify that all wiring is secure and free from fraying, as damaged wires can lead to short circuits.

Once the generator and connections are assessed, I will proceed to measure the output voltage using a multimeter. This tool is indispensable for determining whether the voltage is within the expected range. If the voltage output is insufficient, it might indicate a failing component that requires replacement.

Additionally, I will evaluate the storage unit responsible for holding the generated energy. Checking the charge level and ensuring that the terminals are clean can make a significant difference in performance. If the charge seems low, it may be necessary to consider whether the storage unit is functioning properly or if it needs recharging.

Throughout this process, I will take notes on any irregularities I observe. This documentation can be invaluable for future reference and can assist in diagnosing ongoing issues. By meticulously following these steps, I can ensure that the energy supply mechanism is well-maintained and functioning optimally, ultimately leading to enhanced performance of my outdoor equipment.

Step-by-Step Evaluation of Your Equipment’s Power Supply

In this section, I will walk you through a comprehensive procedure to assess the vitality of your equipment’s power supply. It’s essential to ensure that everything is functioning optimally, as a reliable source of energy is crucial for performance and longevity. The evaluation process involves several steps that will help identify any underlying issues and confirm that the power generation components are in good condition.

Preparing for the Assessment

Before diving into the evaluation, it’s important to gather the necessary tools and materials. Having the right instruments at hand will make the process smoother and more efficient. I recommend having a multimeter ready, as it will be your primary device for measuring voltage and current. Additionally, ensure you have safety gloves and goggles to protect yourself during the examination.

Conducting the Evaluation

Start by examining the connections and wiring associated with the power supply. Look for any signs of wear, corrosion, or loose connections that could affect performance. Once you have confirmed that the physical components are intact, proceed to measure the voltage output. With the multimeter, check the voltage at various points to ensure it meets the manufacturer’s specifications.

If the readings are lower than expected, it may indicate a problem with the energy generation components. In such cases, further investigation into the integrity of the components is necessary. Additionally, listen for unusual sounds during operation; any irregular noises may hint at deeper issues within the mechanism.

By following these steps, I can systematically evaluate the power supply and identify any potential problems. This methodical approach not only aids in troubleshooting but also helps maintain the longevity of my equipment.

FAQ

What are the signs that my lawn mower’s charging system might be failing?

There are several indicators that your lawn mower’s charging system may be malfunctioning. Firstly, if you notice that the battery is frequently dying or not holding a charge, this could be a sign of a failing charging system. Additionally, if the mower starts to have difficulty starting or the engine runs inconsistently, these could also be symptoms. Lastly, if you see any corrosion on the battery terminals or hear unusual sounds coming from the charging system, these could indicate underlying issues.

How can I test the charging system on my lawn mower?

To test the charging system on your lawn mower, you’ll need a multimeter. First, ensure that the mower is turned off and the battery is disconnected. Set your multimeter to the DC voltage setting. Reconnect the battery and start the mower. Once the engine is running, place the multimeter probes on the battery terminals. You should see a voltage reading between 12.6 to 14.5 volts. If the reading is below this range, your charging system may not be functioning properly. If the voltage is significantly higher, this could indicate an overcharging issue.

What tools do I need to check my lawn mower’s charging system?

To effectively check your lawn mower’s charging system, you will primarily need a multimeter to measure voltage. Additionally, having basic hand tools, such as a wrench set or screwdriver, can be useful for accessing the battery and charging components. If you suspect that the battery itself may be the issue, a battery tester can also be helpful to determine the health of the battery.

Is it safe to work on my lawn mower’s charging system myself?

Yes, it is generally safe to work on your lawn mower’s charging system yourself, provided you take the necessary precautions. Always ensure that the mower is turned off and the battery is disconnected before you begin any work. Wear safety glasses and gloves to protect yourself from any acid spills or electrical shorts. If you’re unsure about any step or if you encounter issues that seem beyond your expertise, it’s a good idea to consult with a professional mechanic to avoid potential hazards.